Mathevon provides its manufacturing services on three continents to ascertain full understanding of all your needs.

Production facilities specifically designed for super-alloys capable of machining parts weighing up to 3.5 kg and measuring up to 2.1 m long.

A broad range of anti-wear and anti-corrosion coatings: Xylan®, Phosphate conversion coating, HVOF…

Production facilities specifically designed for machining and finishing processes for the cladding of parts measuring up to 6 m long and weighing up to 10 t.

Equipment specifically designed for the machining of super-alloys and anti-corrosion coatings.

Machining

Milling

Turning

Wire cutting

Surface grinding

Lapping

Low stress stamping

Shot Peening

Xylan®

MOS2

HVOF (GV50, CW15)

Metal Lab

Phosphatation

Level II certification

Welding Visual

UT

MPI

DPI

Hardness testing

Raw materials NDT

Welding

Heat Treatment

Machining NDT

Coating

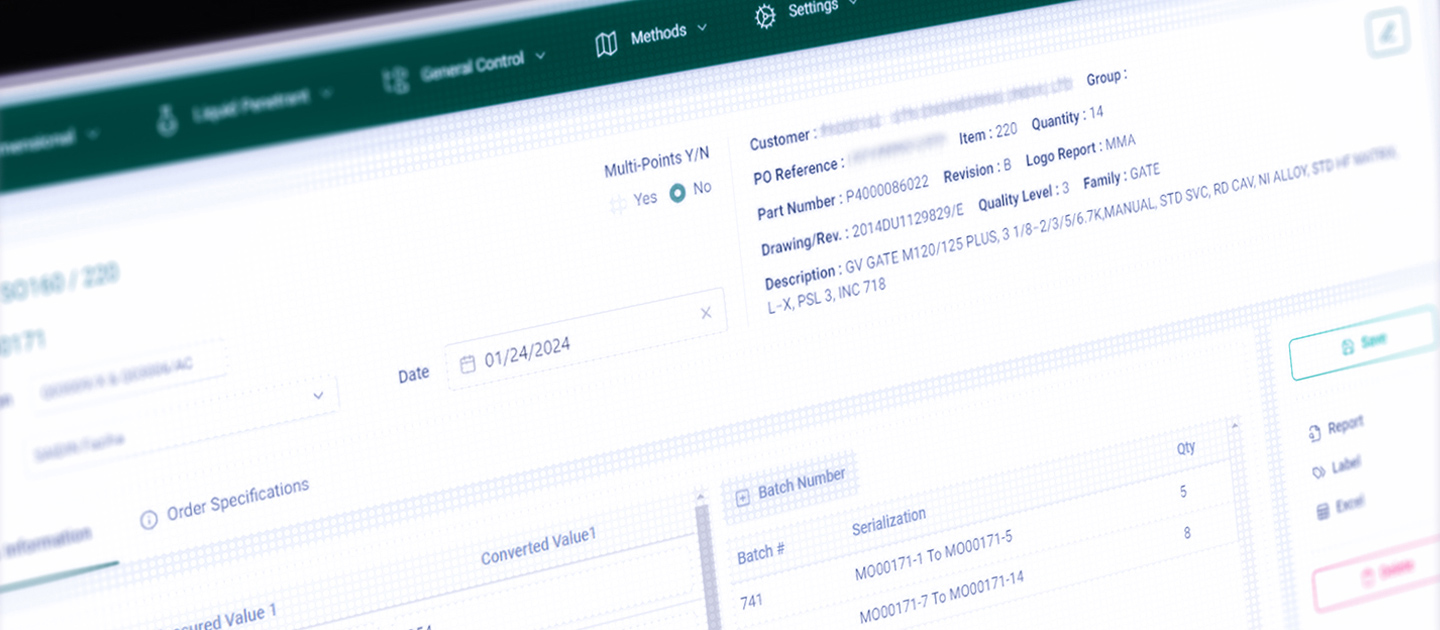

Dematerialization of all of our processes to enable access to quality control reports, traceability and order tracking, regardless of the production site location.

Deployment of innovative state-of-the-art systems to ascertain we provide solutions to our partners’ full range of requirements while abiding with stringent environmental policies.

The Mathevon group has developed non-destructive testing expertise in all its subsidiaries:

– Liquid Penetrant Testing

– Magnetic Particle Inspection

– Ultrasonic Testing

– Hardness Testing

– Positive Material Inspection

Mathevon group boasts a full range of dimensional inspection equipment:

– 3D CMM

– Optical Scan

– Profilometer

– Conventional Inspection Devices

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.